Locating Rods

General

Locating rods are ideally suited for pulling in cables, creating a pilot line, or inserting probes into pipe runs and molded fittings for the purpose of locating pipe routes and pipe breaks.

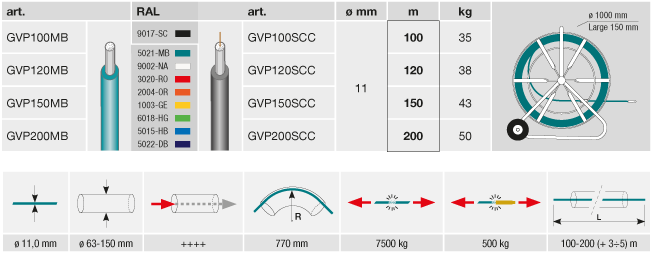

All locating rods are mounted in a galvanized steel tubular frame with ball bearings. Furthermore, the rods are equipped with a braking device to prevent unintentional unwinding of the fiberglass rod. All fiberglass rods feature threaded start and end sleeves to allow the connection of probes and accessories. Depending on the version of the locating rod, mobile frames with wheels as well as frames without wheels are available, allowing the reel to be repositioned more easily and flexibly.

Fiberglass Rod Construction

The fiberglass rod consists of a composite material made of a continuous fiberglass bundle and a high-strength plastic sheath. Thanks to the composite material, the fiberglass rod offers high tensile, breaking, and bending strength, which may vary depending on the diameter of the fiberglass rod. The plastic sheath is designed for high mechanical loads and protects the fiberglass core, including the copper conductor, from wear and corrosion.

Depending on the version, copper conductors may be integrated into the fiberglass bundle. These copper conductors are continuous and connected to the reel frame. The integrated copper conductor can be energized using a standard cable and line locator. This makes it possible to locate the inserted locating rod positionally and determine its depth. An integrated copper conductor does not increase the tensile, breaking, or bending strength of the fiberglass rod.